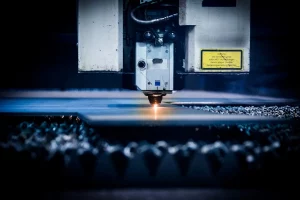

The advantages of CNC machines continue to make them a good choice for the medical industry. Their ability to precisely engrave, mill, and cut metal makes them an essential resource in the production of prosthetics and other medical devices used for human augmentation. The ResMed AirFit F20 is a popular example of a medical device that benefits from the use of CNC machines. This mask is an essential component for individuals suffering from sleep apnea, a condition that causes temporary breathing interruptions during sleep.

CNC (computer numerical control) is a technology that makes use of computers to automate machine tools like lathes. CNC can make complex 3-D shapes, making it beneficial for the medical industry. Because of this, there has been an increase in demand for these types of machines within the medical industry.

CNC machines are used to produce a huge range of products for the medical sector. Examples include orthopedic implants, dental prostheses, and artificial organs such as hip joints.

The Benefits of using CNC Machines in the Medical Sector:

1. Increased Accuracy

In order to make accurate metal parts for medical applications, extensive machining is required. In order to achieve the desired accuracy, a machine tool normally needs to cut extremely close to its workpiece.

This requires a lot of experience and skill from the operator controlling it. CNC machines provide increased accuracy by being able to maintain the same tolerances as a manual or a simpler machine tool. The reduced variation in tolerances provides reduced rejection rates and better quality medical products.

2. Higher Volume Of Parts

Since CNC machines are more accurate than manual or conventional machine tools, they can produce large volumes of parts per day. This saves time, which is crucial in the medical industry where supplies need to be delivered in a timely manner.

For example, in the orthopedic industry, CNC milling machines can produce large numbers of parts per day that an orthopedic technician then uses to create artificial joints or fix broken ones.

3. Customization

Usually, in most conventional machine tools, it is possible to configure some features which are important for specific applications like manually operated tools and automation.

4. Cutting Tool Life

Though there are high-efficiency milling machines in the market, they are not that efficient when it comes to cutting tool life. It is because of this that electric discharge machining is used, which ensures that the tool lasts longer while at the same time saving on costs. This process involves an electrical spark that removes excess material from the surface of the metal.

5. Flexibility

This is another good quality that comes with modern machines. It mostly involves the ability to program them using computers or computer-aided design (CAD). This further enhances their functionality based on application needs.

6. Reduction On The Time Taken On Job Completion

Manual milling is a lengthy process that can waste a lot of time and money compared to using CNC machines. This is because CNC machines are fast, accurate, and come with continuous operations functionality.

7. Material Saving

Another benefit of these machines lies in their ability to reduce the wastage of materials. This is because they can perform multiple tasks on a single block without damaging it in any way.

8. Durability

These machines are manufactured from strong and durable metals such as aluminum, steel, and iron. Their design makes them more reliable, even at high operational speeds. The internal working of these machines is also very smooth, making them less prone to damage.

9. Improved Production Rate

The efficiency of CNC machines cannot be matched by other conventional manufacturing processes. This is because they are equipped with hardware that makes them capable of handling more tasks every day. Also, the fact that they can operate without human assistance means that skilled labor can be used for more important projects or tasks.

10. Easy To Use

All CNC machines come with a comprehensive user manual that is written in simple language and has easy-to-understand illustrations. These step-by-step guides make it a lot easier for a novice to operate the machine, as compared to older technologies that required advanced training even to operate them.

Additionally, some CNC machines come equipped with software packages that are easy to use by non-technical persons. Therefore, even if you have no experience of working on a CNC machine before, chances are that you will be able to start using it right away after reading the user manual. It is easier when dealing with Topas medical grade plastics.

There are as easy as the thermal mass flow calibration.

Conclusion

CNC machines are easy to operate, even for beginners. And in an industry that focuses on the health of people, this is very important. Therefore, it can be said that CNC machines are beneficial to the medical sector. They allow for more accurate measurements and faster results than older technologies used in the past.